Another Engine Build

| JasonB | 16/04/2020 08:34:36 |

25215 forum posts 3105 photos 1 articles | It will be OK, just watch that you get a seal around the outside of the notch when you assemble the engine as the area is a bit less. I tend to use a liquid gasket rather than paper but it will run OK without a gasket. |

| Ron Laden | 16/04/2020 08:57:10 |

2320 forum posts 452 photos | Thanks Jason, hopefully I wont need a gasket but if I do I see ARC stock 742 Gasket Eliminator is that what you use. |

| JasonB | 16/04/2020 10:51:42 |

25215 forum posts 3105 photos 1 articles | Similar stuff |

| Ron Laden | 17/04/2020 08:03:07 |

2320 forum posts 452 photos | Apart from honing the cylinder is finished, there is something very satisfying producing parts like this from a block of bar stock, well for me anyway. |

| Ron Laden | 17/04/2020 15:54:48 |

2320 forum posts 452 photos | Hi Jason, Just about to start on the valve chest and valve parts, I dont have any 2.5mm rod or a reamer but I do have them in 3.0mm. Would I be ok in changing up to 3.0mm I would need to thread the valve nut M3 and I guess modify the valve rod slot from 4 to 3.75mm..? or is it best I stay with 2.5mm, I can order in some 2.5 and a reamer if it its best to stay with that size. Ron |

| Ron Laden | 17/04/2020 20:19:23 |

2320 forum posts 452 photos | Thought about it a bit more and will stick with the 2.5mm as per the drawing. |

| JasonB | 17/04/2020 20:21:13 |

25215 forum posts 3105 photos 1 articles | You could do it without reaming or use 3/32 if you have imperial |

| Ron Laden | 19/04/2020 07:35:28 |

2320 forum posts 452 photos | Morning Jason, In your build note for the base you mention that you hand ground a blunt cutter to machine the decorative moulding did that cut both the 2mm step and the 2mm radius in one. I have a couple of blunt cutters, I thought I would have a go. Ron |

| SillyOldDuffer | 19/04/2020 10:31:33 |

| 10668 forum posts 2415 photos | Posted by Ron Laden on 17/04/2020 08:03:07:

Apart from honing the cylinder is finished, there is something very satisfying producing parts like this from a block of bar stock, well for me anyway. Excellent, but if made from one piece of bar stock how did you do it Ron? My similar version was made as two parts brazed together because I couldn't think of an easy way to make it as a single object. So, I made a cylinder with flanges and a separate valve block to fit the cylinder. My version: Being self-taught I'm never quite sure I'm doing it right and I'm certainly not efficient! Dave

|

| JasonB | 19/04/2020 10:37:02 |

25215 forum posts 3105 photos 1 articles | You need to read my build article Dave which will walk you through the method step by step with pictures as well Actually I also do them your way sometimes depending on the particular cylinder, just that as this one was designed for a relative beginner it avoids silver soldering, though in a lot of cases JB Weld will do. |

| Ron Laden | 19/04/2020 10:52:15 |

2320 forum posts 452 photos | Hi Dave, yep nothing clever on my part I just followed Jasons build guide, though I have done it this way on 3 previous cylinders so I am becoming an old hand at it now... |

| SillyOldDuffer | 19/04/2020 12:40:44 |

| 10668 forum posts 2415 photos | I shall read the master's words! I was OK in this thread up to Ron's photo:

It's the magic where the sharp top edges are smoothed into the cylinder that has me beat. I shall look at ME4618 and Jason's Build Thread later! I ought to have a go at another engine. I started collecting stuff for Jason's flame licker ages ago and have been repeatedly diverted. Lack of discipline... Ta Dave

|

| Ron Laden | 21/04/2020 10:34:01 |

2320 forum posts 452 photos | I would like to present my comedy of errors, I could have rectified it first but no point in hiding your mistakes. I have made the valve chest its cover and fitted and shaped the valve gland and its boss, you can probably see that things dont look quite right . Firstly the sides of the chest and the cylinder dont match, the dimension side to side is 27mm. The chest is spot on the cylinder is 27.6mm (dont ask) so needs 0.3mm skimming off each side to match the chest. You can also see that the top face of the chest is too low by 0.9mm there are two reasons, the first is my error when shaping the gland and boss using the boring head I went too deep. A pretty poor show really when you consider I was working to a DRO setting. The second reason is that towards the bottom of one of the plunge cuts the tool grabbed and dug in about 0.2mm, cant explain that one as all the other cuts had no problem. So it will be a case of getting out the JB to build up the top face to the correct height, anyway the shaping of the gland and boss turned out well so thats one blessing at least.

|

| JasonB | 21/04/2020 13:05:53 |

25215 forum posts 3105 photos 1 articles | Ron. if you wrap a bit of brown vinyl packing tape or even masking tape around the chest it will act as a dam to stop the JBWeld running down the sides, once set file the edges flush and probably turn the top in the 4-jaw. never the easiest to do without the tool catching if teh bottom of it is fairly flat but could have been worse, I blame the recycles iron

|

| Ron Laden | 21/04/2020 13:58:25 |

2320 forum posts 452 photos | Thanks Jason for the tip of using the tape, sounds a good plan. Looks like I was lucky and got off lightly, I also had fun and games yesterday turning up the valve gland. I am a big fan of GT inserts but struggled with them yesterday on the bronze gland, I was taking 1.0mm cuts taking the 16mm down to the 5mm spigot and tool dug in twice, changed to 0.5mm cuts but still the same problem. So I changed to a MT insert and problem solved, I am guessing that the GT,s are too sharp for brass and bronze, though I turned the main bearings with a GT no problems but no more than 0.25 cuts. Ron Edited By Ron Laden on 21/04/2020 14:00:09 |

| Ron Laden | 22/04/2020 13:13:54 |

2320 forum posts 452 photos | Should anyone be in need of metals, M-machine are still up and running. I just phoned them and ordered some material for the engine which they hope to cut and ship out today, cant beat that for service considering the current situation. |

| Ron Laden | 24/04/2020 07:19:09 |

2320 forum posts 452 photos | Made the adjustments, the cylinder sides and the chest now match. Plus I have increased the height of the chest with JBWeld after my machining error. I am in two minds how to finish the top of the chest, I am tempted to curve the edges down to meet the top of the chest cover and the cylinder. When the JB settled out it produced a nice curved fillet around the boss, looks quite casting like. I have also added the cylinder cover.

|

| Ron Laden | 24/04/2020 14:19:15 |

2320 forum posts 452 photos | Posted by Ron Laden on 22/04/2020 13:13:54:

Should anyone be in need of metals, M-machine are still up and running. I just phoned them and ordered some material for the engine which they hope to cut and ship out today, cant beat that for service considering the current situation. I am impressed, I ordered on Wednesday at 12.00 and the order was delivered at 10.00 this morning. On checking the order one item was the wrong size, phoned them and they told me to keep the wrong item and the correct size piece will be FOC and despatched this afternoon. They will certainly be getting my business again.

|

| Ron Laden | 29/04/2020 16:27:48 |

2320 forum posts 452 photos | Made the entablature this afternoon, just needs a clean up. I had made a start on the four columns but gave that up as a bad job. I was using some 10mm bright bar that I had been given a while back, dont know what it is other than rubbish, I tried MT and GT inserts and HSS plus numerous settings but I couldnt get a finish it was like a ploughed field. So I ordered some EN1A and got on with the entablature.

|

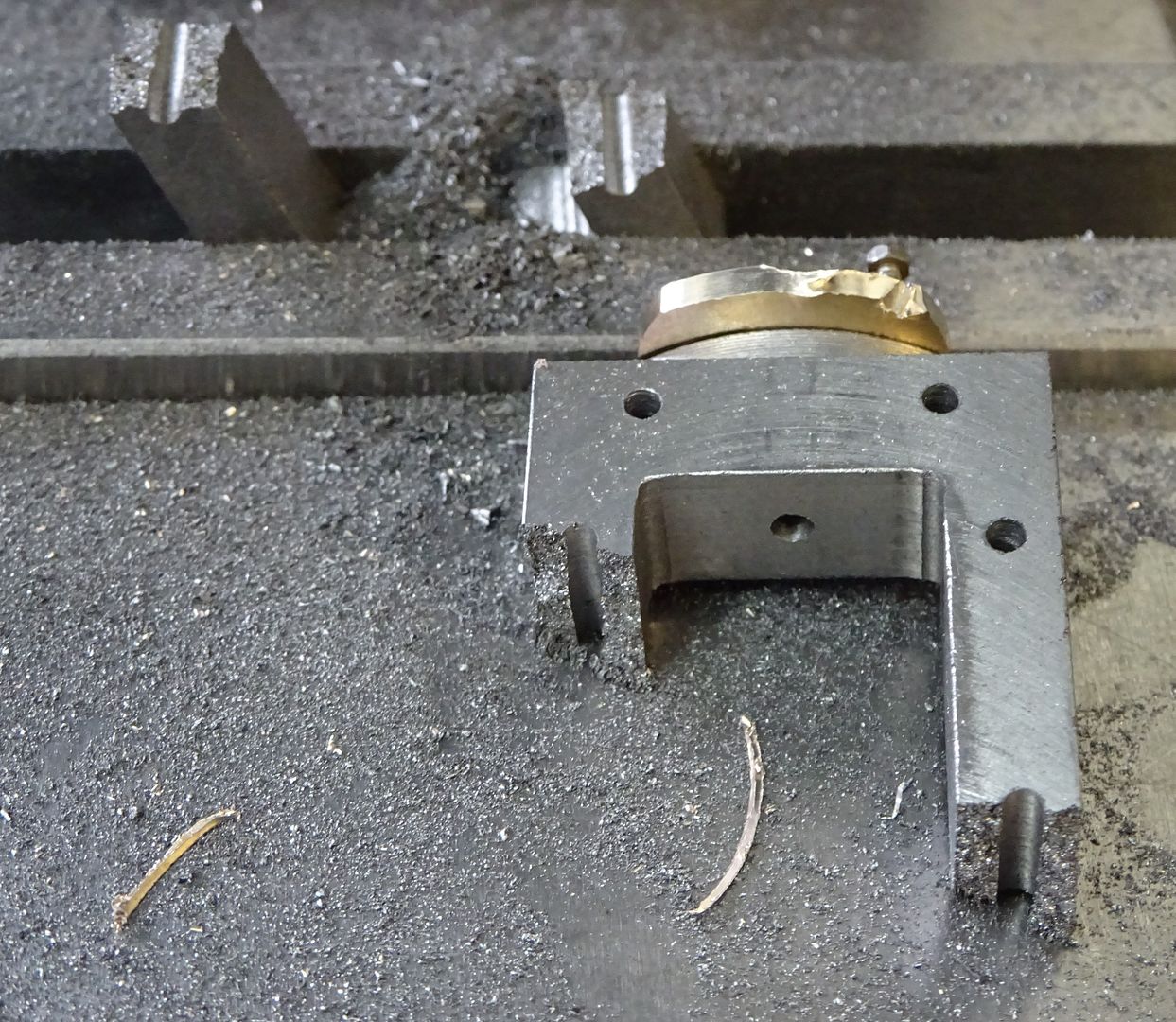

| Ron Laden | 05/05/2020 08:05:53 |

2320 forum posts 452 photos | I managed to fit the base onto the 5 inch rotary to cut the cylinder seat, a bit unconventional way of using the packing pieces. I thought I may have to knock up a mounting plate but just managed to squeeze it on. I dont have a 2 flute 8mm alu cutter so had to go with a 3 flute TiAIN coated HSS but 1750 rpm, 1.0mm cuts and some lubrication and it cut very cleanly. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in