Member postings for John Duncker 1

Here is a list of all the postings John Duncker 1 has made in our forums. Click on a thread name to jump to the thread.

| Thread: Searching for an Off-The-Shelf, Light-Duty, Rack & Pinion |

| 01/08/2019 20:00:01 |

I meter of threaded rod. 1 nut welded to a bracket some swivelling allowance. I electric screwdriver. All cheap as chips. Just hold the driver to stop it turning? You will have side load issues with a rack. |

| Thread: RENAULT DAUPHINE |

| 01/08/2019 19:51:20 |

I drove a recovery truck in the 60s. I can remember attending at least 3 overturned Dauphines each with rather bewildered drivers who could not understand what had happened when they lifted off on the roundabout. |

| Thread: Surplus subjects learnt at school. |

| 23/07/2019 22:20:31 |

Computer programming languages have extremely strict syntax, semantics, grammar and spelling. And computer programming is deeply into patterns and structures, all very formal with tight rules. Curious then that not only is learning Latin not essential to becoming a computer programmer, but in 40 years I don't think I met any computer programmers who had studied it!

Monkey patching programmer here who did Latin to O level under duress. Went on to learn to hack my way through Pascal C C++ and for my sins Dbase. |

| 20/07/2019 17:05:20 |

I was involved in education and found myself co-opted onto an exam board looking to update the school curriculum. This was mostly because I had been a very outspoken critic of the inclusion of things like Latin and Greek. This was in the late 80s and PC computers were affordable. It seemed to me to be very obvious that touch typing would be a useful and transferable skill and should be taught in schools. I also put forward that cursive or joined up handwriting should not be taught as part of the general compulsory curriculum but as an option. I put this forward at large meeting of school heads. It was not well received. In fact about 3/4s of the hall stood up and HOWLED at me. It was as if I had proposed vivisection on the school cat. It was amazing how many of the heads followed up with handwritten letters in beautiful cursive insisting on the retention of cursive in the school curriculum. My suggestion was not adopted. But over the years I have watched with interest the dropping of cursive as a compulsory subject and touch typing creeping into the class room. I was also involved in looking at alternative routes into degree level courses with a number of admission tutors. It rapidly became clear that of all the topics required maths was almost the only one that could not be successfully taught in remedial classes. I am part of the group that think that there is a time in the brains development during which the language of mathematics can be acquired. It is around 12 years of age. Few people older than 16 can successfully acquire a good understanding of maths. I watch with some despair as the maths syllabus is dumbed down in many schools and even universities.

|

| Thread: Angle grinders - Dangerous or not |

| 17/07/2019 17:00:05 |

There is an old adage in the sailing world. " Fools build boats for wise men to sail" Somewhat cruel but applicable. build log The started building in 2006. 13 years ago. They are no way near finished. They could have taken a 1/4 of what they have spent to date, bought a boat in 2006 and gone sailing. The sad thing is they may make it to completion and launch only to find they don't enjoy the cruising life. Me I love it but I have seen some sad cases of abandoned dreams. Sometimes scared sometimes ill sometimes just bored and the boat goes up for sale and they fly back to living on land. Edited By John Duncker 1 on 17/07/2019 17:01:15 |

| Thread: Model Engineering Overseas |

| 25/06/2019 17:22:01 |

Posted by Hopper on 25/06/2019 09:16:07:

Posted by Haggerleases on 24/06/2019 17:21:54:... ...I always find it quite fasicinating to read of people who have carried on their hobby in challenging circumstances...

You would enjoy this article then about a small lathe made by inmates of a Japanese POW camp in WW2 LINK A truly amazing story. |

| Thread: The World of Buckminster Fuller |

| 21/06/2019 20:44:22 |

As well as the geodetic dome he was responsible for some of the longest and most convoluted sentences ever written. He also wrote a history of the world which included a section on Mrs Buckminster Fuller choosing curtains. He was a student party animal which got him expelled from Harvard. An interesting man. |

| Thread: Mini Lathe footprint dimensions and will it slide |

| 15/06/2019 16:49:38 |

Lots of ideas here to work on. Yes I will have a small vise with an anvil for light bashing. Serious bashing gets done ashore. The lathe will be locked down on passage probably with a couple of through bolts and wing nuts. As to dealing with wakes I guess I need a short tie which allows me to push it back and forward but stops it coming off the shelf. As to neatness well I suffer from a variation of Murphy's law which says that I will cover any flat surface with random stuff. So don't tempt me with extra shelf space, I will just fill it. |

| 14/06/2019 21:10:43 |

Posted by AdrianR on 14/06/2019 18:02:57:

As you have bulkheads, If you have any height above or bellow the lathe you could have it swing on a parallelogram at each end. Or with a trapezoid linkage it could tip back out of the way. Just need some stainless bars and bolts. Do you even need a shelf? just bolt it directly to some box section. That is an interesting idea. Yes I do have space above and below where I would have the shelf which is also my workbench. Above would be simplest with a 4 or 6 part pulley to lift and a some kind of linkage to control the position. I have just had a play with a couple of wire coathangers and the linkage is doable. with one solid strut and one wire link on each side. My initial idea was to just push the lathe to the back of the shelf which would give me a strip at the front about 12 inches wide as a workbench. Lifting the lathe up and back gives me the whole shelf as a workbench. Hmm do I need that space. |

| 14/06/2019 17:24:42 |

The shelf is not to be cantilevered off a vertical surface but fitted between bulkheads. I am in a marine environment so avoid materials like MDF and mild steel. regardless of coating in a situation where it will wear. So standard household stuff is out. My first trawl through the internet for stainless steel heavy duty drawer slides came up with this LINK With a 352 lb capacity they should survive even a rough interisland passage with the dreaded Caribbean 2 step running. These are short steep waves and everything bangs about when you come off a wave. I could fit them reversed so that when the lathe is pulled forward for use the slides are in the closed position and pushed back would be open. But I like simple solutions and might start with stainless steel feet running over Formica.. I could always add the slides if needs be. I will of course have some kind of positive lock for use when sailing. |

| 14/06/2019 16:55:22 |

Posted by Bob Stevenson on 14/06/2019 08:18:34:

I used a Cinese mini-lathe (Chester Conquest) for about ten years and grew to like it,....I mostly made my first clock on it along with much other stuff. Compared to other lathes of my experience the mini-lathes are 'quirky', one of these being the rubber feet which are quite close together front to rear. At higher speeds my lathe 'waddled' about on the bench and at the highest speed rocked back and forth. Needless to say i never go to like that 'quirk' and plotted and planned to eliminate it by making four cut-outs for the feet in 18mm ply. However, eventually I just removed the rubber feet and replaced them with stainless disks about 4 inch in diameter. This simple solution turned my mini-lathe into a different machine,..quite literally! Edited By Bob Stevenson on 14/06/2019 08:20:16

Thank you that is an excellent idea. The extra weight stabilizing the lathe and the stainless will slide more easily than the rubber. |

| 14/06/2019 02:38:25 |

I m in the process of setting up a shelf for my 7 x 12 mini lathe.The width will be 31 inches and the depth around 24 inches. I will use 1 inch marine ply possibly laminating two pieces of 1/2 inch depending on availability. Can anyone confirm that the 7 x 12 is 770mm or 305⁄16in wide? To make the best use of my limited space [ I live on a boat ] I will want to push the lathe to the back when it is not in use and pull it to the front when I am turning something. I gather it comes with rubber feet. If I want it to slide easily what surface finish should I use on the shelf ordinary white paint, epoxy floor paint formica aluminium sheet or stainless steel sheet. ? Maybe using a squirt of WD 40 ? Edited By John Duncker 1 on 14/06/2019 02:39:45 |

| Thread: Electricity Supply |

| 09/06/2019 21:34:16 |

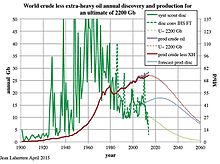

World oil discoveries peaked in the 1960s The peak of world oilfield discoveries occurred in the 1960s[16] at around 55 billion barrels (8.7×109 m3)(Gb)/year.[75] According to the Association for the Study of Peak Oil and Gas (ASPO), the rate of discovery has been falling steadily since. Less than 10 Gb/yr of oil were discovered each year between 2002 and 2007.[76] According to a 2010 Reuters article, the annual rate of discovery of new fields has remained remarkably constant at 15–20 Gb/yr.[77] The people who made the above statements were not loonie save the planet beardy weirdies but top people in their fields. A major world wide energy crunch is coming, probably around 2030. Unfortuneatly a major world wide food crunch is also coming around the same time.The water crunch is here now in some places and will be spreading world wide maybe around 2030. I was in Utah earlier this year and filled my fuel tank for 2.27$ a gallon. Why is it so low well the American govrnemnt subsudise the search for oil and the development of new production sources. We are talking billions. The American leaders know that there is a short term gain for their economy and their popularity at the polls if they keep fuel prices low. But it can not go on forever. Sure we can switch to electric cars and trucks but where are the new power stations and what will fuel them? A back of a fag packet calculation shows we can only generate enough for a small fraction of todays trucks and cars.unless we build a shed load on nuclear power plants like the French. By 2050 it is pretty clear that supplies of oil and gas will be declining rapidly, this will lead to world wide famine which will hit China and India hardest. Both countries have nuclear weapons. The fall of civilisation is 4 square meals away

|

| Thread: Small air compressor sufficient to run a Potty Mill |

| 02/06/2019 18:09:51 |

Thank you for the out of the box thinking. The boat is a 44 ft cutter with a venerable Japanese built Perkins 4-154. Alas there is no engine driven compressor. My boat does not have a spare wheel. It does have an inflateable dinghy and pump, however the max tube pressure is around 5 psi. In the past I have used plastic bottles to store compressed air. A typical 2 liter pop bottle bursts at around 120 psi so keeping to about 30 psi is usually safe. I will probably make a first run directly off the little EBAY pump and only go down the silent pop bottle route later. I can make a widget to vary the air supply from the bottle. I am in the West Indies and it is easier and cheaper to buy stuff in the USA and ship it down as one consolidated load all marked spares for yacht in transit. This gets me a much lower import tax band.of 2 or 2.5 % Also some sellers refuse to ship outside the lower 48 states of the USA. So I am doing some careful planning |

| 01/06/2019 02:21:56 |

Posted by Malc on 31/05/2019 22:45:06:

Hi John, I have just finished building a beam engine the bore of the piston is 30mm and the stroke is about the same. I was faced with the same question of how small a compressor could I use to test run it. I only had one of those tyre inflation jobs so I tried it plugged into the 12 volt car supply but it was not quite keeping the engine running - almost but not quite! I have a PSU which I made up to run a cordless drill which had a dead battery it produces about 18 volts. I hooked up the tyre compressor to the PSU and it increased the speed sufficiently to test run the beam engine. A bit cruel on the tyre compressor but it was only for a test run. It was suggested by someone on this forum that a tank such as a plastic bottle would help. Don’t know how your Potty Mill compares to a beam engine? But I thought this little tale might be of interest. Good luck with it, Malc. Thank you for confirming that it is possible. I have a PSU that delivers 17 volts and I can try that. I only want to run it for a couple of minutes at a time just long enough to enjoy the fruits of my labors. I will probably charge a pop bottle up to 30 - 40 psi and shut the compressor off as they are noisy little suckers and that way I can listen to my running engine. |

| 31/05/2019 20:50:07 |

I need a small air compressor sufficient to run a Potty Mill 16 mm bore 32 mm stroke Will this sort of thing do do ? I suspect not. I guess I can use it to build up some pressure in an air reservoir [ plastic coke bottle ] then use that. Space and weight matters as my workshop is a tiny cubbyhole on a boat. |

| Thread: Colchester Lathe Factory |

| 30/05/2019 16:57:15 |

In the 80's I worked at Loughborough Technical College. We had workshops with rows of Colchesters mostly Students and they were in almost daily use training apprentices on day release from Rolls Royce Hawker Siddley Brush and the like. I went back in 2005 and they were all gone and the word Technical dropped from the name. |

| Thread: Early metal lathes |

| 27/05/2019 20:06:02 |

Posted by Haggerleases on 27/05/2019 19:04:44:

I thought a steam engine, loco or clock would be good as it's a bit more substantial than balsa and tissue.

Ah but will it fly? |

| Thread: Potty Mill engine materials list wanted |

| 21/05/2019 15:21:34 |

The plans I have were drawn by JDW of New Zealand and cover 4 A3 sheets. I downloaded it from the internet. They look OK to me and incorporate a parts list. The thread sizes are metric and I will need to decide weather to go metric or convert the sizes to the more easily obtainable US imperial sizes. While scrounging up the bits might be possible it would be very hot and tiresome with expensive taxi rides to some locations in Grenada. In the past I spent a year trying to hunt down a piece of 1/2 inch ali bar to replace a broken hatch support without any success. Even the famous floating workshop in Carriacou did not have anything suitable. . I would much prefer to order all the bits of bar stock from a US metal supplier like onlinemetals.com. That way I know that I have what I need. Being a US based supplier means I will find imperial sized bar stock. I will probably use US sized nuts bolts taps and dies. If I went the BA route I would need to order from the UK. Edited By John Duncker 1 on 21/05/2019 15:31:00 |

| 20/05/2019 22:45:16 |

I think I will try to make a Potty Mill engine using only bar stock, I was thinking of the Stuart twin wobbler but I think it really needs a mill and I just do't have the space. Also having watched a vid of a build the bits are on the small side for my failing vision and fat fingers. I can work my way through the Potty Mill parts list going back and forth to the dimensions on the drawings to make a materials list. But is this just reinventing the wheel. Has someone made such a list already and is it available online? I would really like to get everything I need in one go as I live on a sailboat in the Caribbean and the supply chain involves multiple visits to local customs officers shipping agents and some serious bureaucracy |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in