ML 7 DC motor powered leadscrew ?

| Hopper | 15/03/2017 11:22:06 |

7881 forum posts 397 photos | You might also be able to use an old battery-powered pistol drill, running on a fixed 12 volt or 14 volt supply and using the original trigger unit from the drill as speed controller, rigged up to an eccentric for control. |

| Jon Gibbs | 15/03/2017 11:26:06 |

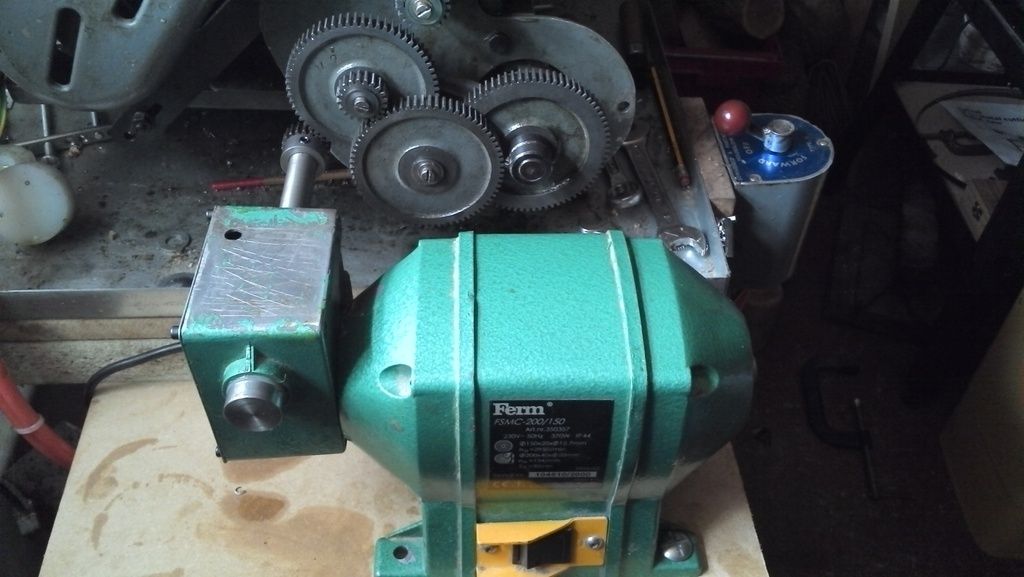

| 750 forum posts | Sid, Have you seen the fine feed arrangement Martin Cleave came up with for his ML4? If you just relocate the banjo to a lower position for the motor drive onto an aligned pinion gear it still leaves open the possibility for thread cutting and you can also use the leadscrew handwheel if you need it. Here's a bodge I knocked up to test the idea and it worked ok but my motor was restricted to fixed speed only which proved too inflexible.

Hopefully you can come up with a better idea. MrPete222 on YouTube has a motor driven leadscrew on one of his lathes but I can't help thinking that the leadscrew handwheel is too handy to make obsolete for me but we're all different I suppose. HTH Jon Edited By Jon Gibbs on 15/03/2017 11:27:00 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in