Member postings for Ron Laden

Here is a list of all the postings Ron Laden has made in our forums. Click on a thread name to jump to the thread.

| Thread: Electric Traction Engine |

| 06/10/2019 08:58:42 |

Finished the test rad with a medium and fine file followed with an emery wrapped file. I thought a couple of light coats of paint would show up the finish and shape, quite pleased with it, if I can copy that on the cylinder I will be happy. . |

| 05/10/2019 16:50:14 |

Should have the alu block for the cylinder Monday and not having milled an outside radius before thought a bit of practice could be useful. The length of the cylinder block will be 60mm but I only had a piece of 30mm but ok for practice. I was thinking of cutting the rad with the side of an end mill but at 60mm and even with a long series cutter I would still need to turn it over and cut it from both ends. I then remembered from one of Jasons build threads him cutting a radius with a series of facets and finishing by hand, that seemed a good idea so gave it a try. I worked around the rad in 3 degree increments and must admit it wont need too much work with the file for a good finish (thanks Jason). I did machine away the bulk in advance so it wasnt too many cuts for the rad, really enjoyed doing it. Edited By Ron Laden on 05/10/2019 16:55:04 |

| 04/10/2019 16:08:48 |

I came across a picture of a Wallis and Steevens roller, what an odd looking engine with the boiler slanting steeply down towards the rear. At first glance it looks as if the boiler is broken into two and collapsed, certainly different though from a modelling point of view, I cant imagine there are too many of those around. |

| 03/10/2019 08:00:04 |

Another of my basic working sketches showing the cylinder at actual size, I have indicated the 3.5" block it will come from. I have drawn the bore at the size it would be with a piston and liner but of course there is no piston so it will come down to 12mm dia. I am going to extend the cylinder cover into the bore to offer a bit more support for the piston rod, probably by about 5 mm that will make the cover 20mm deep overall, the piston rod is 6.5mm dia. Thats the plan anyway. |

| 02/10/2019 13:59:08 |

Just ordered a 3.5 inch square piece of ali for the cylinder block, I am going to try and machine it in one on the mill using the rotary table. I think it can be done or at least I hope so, I have worked out a plan of attack but we will see. Also I have been searching the Minnie drawings for the pin which connects the crosshead to the conrod but of course there isnt a drawing. The pin is described in the build though as a piece of hardened silver steel which runs in the conrod with no bearing. I am going to turn up a thin walled bronze bearing as Jason suggested to me and fit that to the conrod. I have also been thinking about the crosshead guide which on the Minnie are the pair of parallel bars but I do like the idea of the cylindrical guide I have seen on other engines. The ones I have seen have been from castings but I wouldnt imagine too difficult to produce from round bar, dont know yet, undecided. |

| 01/10/2019 17:19:31 |

Posted by JasonB on 01/10/2019 16:17:20:

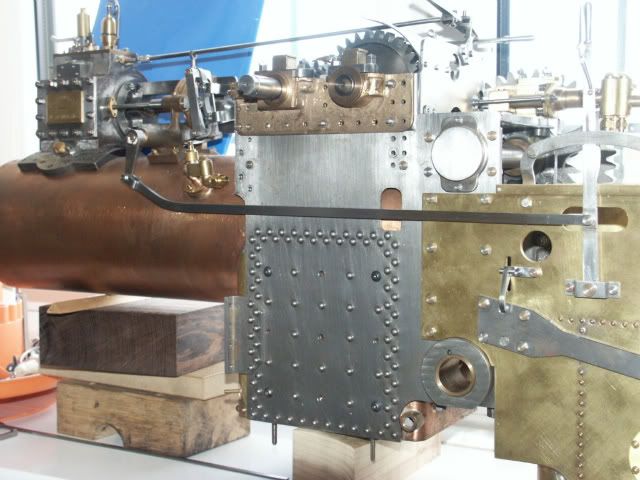

You only need a very shallow CSK infact just deburring the holes will do. Then cut the rivits so they will be just about flush with the inner face and all you need do is ctr punch them which will expand them enough to hold. Dab of Loctite won't do any harm. If you start trying to pein then over to fill a CSK then you will end up with a distorted plate. You could reduce the number of stays by at least 1/3rd and then it is not such a job to reduce the rivirt heads in teh lathe to make them look like stays

Thanks Jason, great advice as always. I was only going to go with a shallow csk but never thought about distorting the plate which I can see now. The ctr punch method sounds quick and easy so thats good. Also reducing the number of stay rivets is good news as I did wonder if I had too many and seeing your picture above I can probably reduce by half. Thanks again. |

| 01/10/2019 13:24:04 |

With a pen and rule I roughed out a layout for the rivets in the hornplate to get a feeling for how they would look. Just based it on a mix of full size and model engines but I think it will look ok. Going to csk the holes on the inner face of the plate and dress back flush. For the stay rivets I,m still trying to find some shallow head type if they exist. Edited By Ron Laden on 01/10/2019 13:30:03 |

| 29/09/2019 11:15:19 |

Thanks Paul, quite a bit more to it than I imagined, I think it probably a good idea if I got a couple of books on TE,s and had a good read. You mention differential, I know I dont need one but I like the idea of having one, Jason posted a good compact design for one a while back. Ron |

| 29/09/2019 10:07:39 |

I wrongly assumed that the layout of the main parts/build of traction engines would be the same or similar across the various manufactures/designs. However looking at some pictures of a scale model Burrell I see it has no second shaft and the high/low gears and shift are fitted directly to the end of the crank. I dont know what type of full size engine the Minnie is based upon but I wonder why they went down that path. Fitting gears to the end of the crank is simpler, cheaper, more compact etc, maybe just a different approach unless there other benefits of a second shaft. |

| 28/09/2019 16:11:32 |

I assembled the crank using 638, I am going to pin the webs but waiting for pins to arrive. I was keen to see if it had turned out true, I havnt clocked it but it looks pretty good by eye so happy with that. A bit of exciting video

|

| Thread: Part built Allchin 1.5 inch |

| 28/09/2019 08:52:35 |

That looks a very sweet runner Derek, you must be pleased with that. Ron |

| Thread: Electric Traction Engine |

| 27/09/2019 08:35:46 |

A shorter version oiler which I,m happy with. |

| 26/09/2019 13:58:36 |

Just wondered are mush head rivets available in model eng sizes, I saw some truss head (I think thats what they were called) but they were very shallow, more so than a mush head. Edited By Ron Laden on 26/09/2019 13:59:14 |

| 26/09/2019 13:47:59 |

Posted by Harry Wilkes on 26/09/2019 13:44:27:

Ron the beauty of making things is if you don't like them you can change or re-make them H Very true Harry, thats a bonus I guess. |

| 26/09/2019 13:17:32 |

No not happy with it, its too tall and the more I look at it, it looks odd. Oh well a re make job. |

| 26/09/2019 09:22:20 |

Made up and fitted the big end oiler this morning, no its not to the Minnie drawing but some parts wont be though the majority will. I found the body in my odds and sods box and it just looked like a potential oiler and about the right size, all I had to do was turn the base under the ball to create a spigot for fitting. Then I turned up a brass cap, its a couple of mm taller than I would have liked but cant do much about that, there is a M4 threaded rod inside the cap which screws into the body and needed the length of cap to thread for the rod. I dont have a knurling tool but managed a light knurl by running the cap along under the edge of a file. Edited By Ron Laden on 26/09/2019 09:25:14 |

| 25/09/2019 21:04:28 |

Thanks Harry, the last link in that thread Nuts and Bolts for Model Engineers do a good range of BA, metric and UNC. They also have a very good range of one size smaller BA plus their pricing looks good. Ron |

| Thread: Surely it's not just me |

| 25/09/2019 21:02:21 |

Oops, sorry posted in wrong thread, deleted it. Edited By Ron Laden on 25/09/2019 21:05:57 |

| Thread: Miitutoyo caliper error |

| 25/09/2019 20:29:53 |

Bob, I have a Mitutoyo Digimatic which is well over 30 years old and it still works but I do have to nurse it along. My problem is battery related also, I have to keep cleaning the contacts or the display dims even with a new battery fitted. Also the central contact which is angled upwards has lost its spring so I have a thin washer between the battery and battery cover to maintain contact. Have you thought of giving the Mitutoyo service dept a call, I have been meaning to but havnt got around to it yet. They may have a standard charge for repair/service of their products, but it may also be a case of replacement parts plus an hourly rate and other charges which costs more than the calliper is worth. I will have to look into it as I would like to keep it going, its till very nice to use and head and shoulders above the cheapo versions. |

| Thread: Track laying |

| 25/09/2019 10:21:08 |

Posted by Derek Lane on 25/09/2019 09:52:37:

A a total novice I have been reading books on model engineering and have just read in a book by Martin Evans that a 3 1/2" gauge requires a minimum radius is 30ft it did not give any for the 5" gauge Thats sounds a lot to me, I would have thought a 3 1/2" could come down to half that radius as a minimum but maybe not, it does surprise me though. |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in