Member postings for Ross Lloyd 1

Here is a list of all the postings Ross Lloyd 1 has made in our forums. Click on a thread name to jump to the thread.

| Thread: Warco lathe owners - what is this feature? |

| 04/06/2018 14:39:45 |

It may just be a bit low and with a very light oil. This is what I can see with my phone camera, looks like a little sliver of oil at the bottom of the glass. This is on the saddle:

Compare that with the one for the gearbox. May be a heavier oil, but is clearly visible.

Reckon it just needs a top up? I did see another thread on here discussing the need to do a full drain and re-oil. |

| 04/06/2018 14:06:54 |

Thanks Trevor, is the fill port that big allen screw on the left side of the apron? I didnt fancy unscrewing things without being sure, even with the big picture of the oil gun under it! Edited By Ross Lloyd 1 on 04/06/2018 14:13:25 |

| 04/06/2018 13:51:57 |

Hi WM250V. What is this feature (circled)? It looks suspiciously similar to the sight gauge for the gearbox oil, however it is not referenced in the manual and neither is a fill point. What is it? If it is a sight gauge, its empty.

Cheers

Edited By Ross Lloyd 1 on 04/06/2018 14:02:49 |

| Thread: New Warco Lathe and Mill |

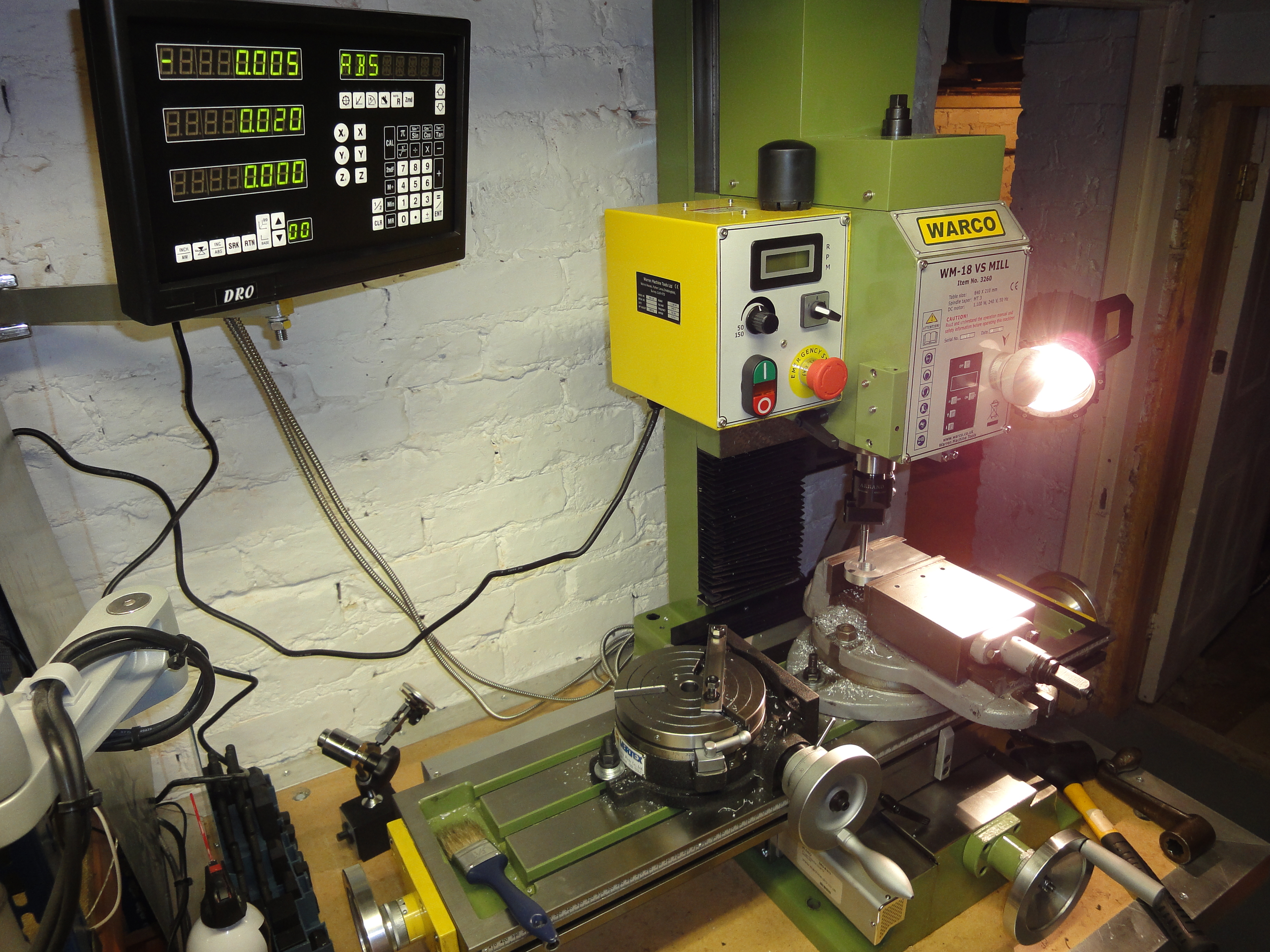

| 02/06/2018 23:52:57 |

Update: The lathe is on the bench. The mill is waiting its turn for the engine hoist, rusty knackered old thing from a local tool hire firm. After a false start where they forgot to supply the leg pins, amazingly it sailed through picking up the WM250V. I've not had a chance to test for twist yet, which may demand buying a digital gauge.

Ignore the improvised shim under those cutters, they were just enough to make some chips on a quick test piece!

Edited By Ross Lloyd 1 on 02/06/2018 23:57:39 |

| Thread: New vice - is it too large? |

| 02/06/2018 23:46:21 |

OK its going back. I spoke with Warco, they recommend a 4 inch for the WM18. I am considering a high end 4 inch. What are the brands to look at? I know Kurt and Glacern for the US market, are there alternatives for the UK? Thanks Edited By Ross Lloyd 1 on 02/06/2018 23:47:45 |

| 31/05/2018 19:46:20 |

Ah I misunderstood, you meant specifically the swivel as opposed to the whole vice itself! Cheers |

| 31/05/2018 19:42:20 |

Hi Jason Yeah taking it off the base will certainly give a bit more room and lessen the weight. I bought one because at the club I go to, the vice seems to be on the mill permanently. Its a big old bridgeport mill that gets a fair bit of use. Some of the members felt it was a good idea to get one, do you find that you have little need for one? Cheers |

| 31/05/2018 19:01:04 |

Hm Just found this piccie online, maybe this is one of our members

|

| 31/05/2018 18:53:32 |

Hi Tim, Yes good point. I definitely wanted the 6 inch length as I have already been doing some jobs on other machines that need that (admittedly it was a full size bridgeport though). Is it possible that the weight of it could distort the table, or am I worrying over nothing? There is quite a lot of z travel left in that axis, I guess also if I run out of room I can just take it off and clamp the piece to the table? Thanks again! |

| 31/05/2018 18:33:50 |

Hi I just ordered this vice from chronos. Its a very nice 6 inch vice. I wondered though, once I had it in my hands, is it a mite big? Or perfectly acceptable for a mill the size of the Warco WM18? Cheers gents Edited By Ross Lloyd 1 on 31/05/2018 18:35:30 |

| Thread: New Warco Lathe and Mill |

| 21/05/2018 13:03:02 |

Hi Thanks all for the suggestions, good to know its more the twist than anything I need to worry about. I will see how we get on and if we are struggling will give the advice Thor gave a try. Cheers

|

| 20/05/2018 17:05:01 |

Hi gents I recently took delivery of my workshop's newest residents, and they are poised to be lifted onto their homes this week once we get the engine hoist! A couple of weeks back a man with a lorry delivered these packages:

Inside was a WM-18 mill: ... and a WM-250V lathe:

The workshop is nearly complete and it will soon be time to lift them onto the new bench! Question to anyone who has installed these - how level does each machine need to be? Can they cope with a bit of tilt or do they need to be bang on (at least to a certain tolerance)? Am going to need to make some standoffs for the lathe as the swarf tray is made to fit their stands, and would not sit flat on a bench. Nearly there though! Cheers Edited By Ross Lloyd 1 on 20/05/2018 17:12:10 |

| Thread: Warco WM18 has arrived |

| 17/02/2018 13:44:55 |

Posted by Vic on 14/02/2018 21:53:12:

Dave delivered my VMC and wheeled it straight into my garage and took it off the pallet. Great service, I even made him a cup of tea for his help! haha good old Dave |

| 17/02/2018 13:44:35 |

Posted by ChrisB on 15/02/2018 06:59:34:

Erm, I have to clarify! I had the machines exported so I couldn't expect poor Dave to come over to Malta and wheel it down the driveway! That said the transport service I used did help me with moving the machines into the workshop, btw I measured the pallet the mill came on, its a EUR pallet, so that's 80x120cm. The mill sat in a crate with a slightly smaller base, 70x100cm OK thats great, should go through the gate no problem! Dave might have quite liked a weekend in Malta. Poor Dave |

| 17/02/2018 13:43:14 |

Posted by petro1head on 15/02/2018 10:07:37:

Just a point. The Mill is much easier to move than the lathe as it can be stripped down into more parts. I ended up removing the table, head and column Edited By petro1head on 15/02/2018 10:16:21 Ah good point. I have heard about a process called "tramming" from US sources that seems to follow a mill strip down. Did you need to do this setup process after dismantling? That was making me leery of taking it to bits |

| 14/02/2018 21:15:24 |

Posted by ChrisB on 14/02/2018 20:27:18:

When I got mine, the truck could only deliver to the curb side, my workshop is a basement garage, and access to it is through a steepish ramp, but with the help of a palletizer we managed quite easily. For lifting the machines I used a 1ton chain block, the benches have caster wheels so I can move them around. http://www.model-engineer.co.uk/forums/postings.asp?th=129962&p=2 No problems with the lathe so far, I only have them since last summer, very happy with it. Have not used the mill much as I only got proper cutters and a vice a couple of weeks ago. What I'll need for sure is a dro. Hm that's a shame about only to the curbside. Some other folks said they wheeled it all the way into their back gardens, even depalletised it. Guess its a case of which guy you get and how he's feeling that day. Yeah I fancy a DRO, but gona see how I go at first without. I also have my eyes on CNC at some point |

| Thread: ChrisB workshop build |

| 14/02/2018 21:11:53 |

Was the mill OK being lifted under the head? I was concerned about putting stress on gear teeth in the z axis. |

| Thread: Warco WM18 has arrived |

| 14/02/2018 18:14:08 |

Posted by ChrisB on 14/02/2018 16:22:57:

Yep, that's right. I still have the pallet somewhere, can measure it for you tomorrow. The dimensions are that warco gave me when I asked them for shipping purposes, did not weigh the mill but on the chain block it felt substantially heavier than the WM280 lathe. I am getting a 250 and a WM18, and hoping the pump truck will make it all the way down our concrete path to the workshop with both. The 250 is much lighter than the WM18 but more of an awkward shape. Once the crates are in the workshop am going to hire an engine hoist to get them up on the bench. Hopefully wont end up with any missing limbs by the end! How are you finding the 280? That's a lot of lathe |

| 14/02/2018 16:04:32 |

Posted by petro1head on 13/02/2018 15:49:18:

Funnily enough, no. However one of the photos shows it near to a wheely bin. Sure you can work it out front that though Cheers, the pictures are great Edited By Ross Lloyd 1 on 14/02/2018 16:05:00 |

| 14/02/2018 16:02:44 |

Posted by ChrisB on 13/02/2018 18:17:12:

The WM18 comes in a crate on a pallet measuring 142cmx80cmx82cm, weighing 255kg. Cheers Chris, so the pallet is 80 x 82? That should fit through my gate nicely! 255kg ... Its a hefty bit of machinery for sure |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

He seems to be coping ok and thats a whopper. Maybe I will be alright

He seems to be coping ok and thats a whopper. Maybe I will be alright

Register

Register Log-in

Log-in