Member postings for Steve_M

Here is a list of all the postings Steve_M has made in our forums. Click on a thread name to jump to the thread.

| Thread: Hobbymat MD65 Electrical Problems |

| 31/12/2015 16:08:26 |

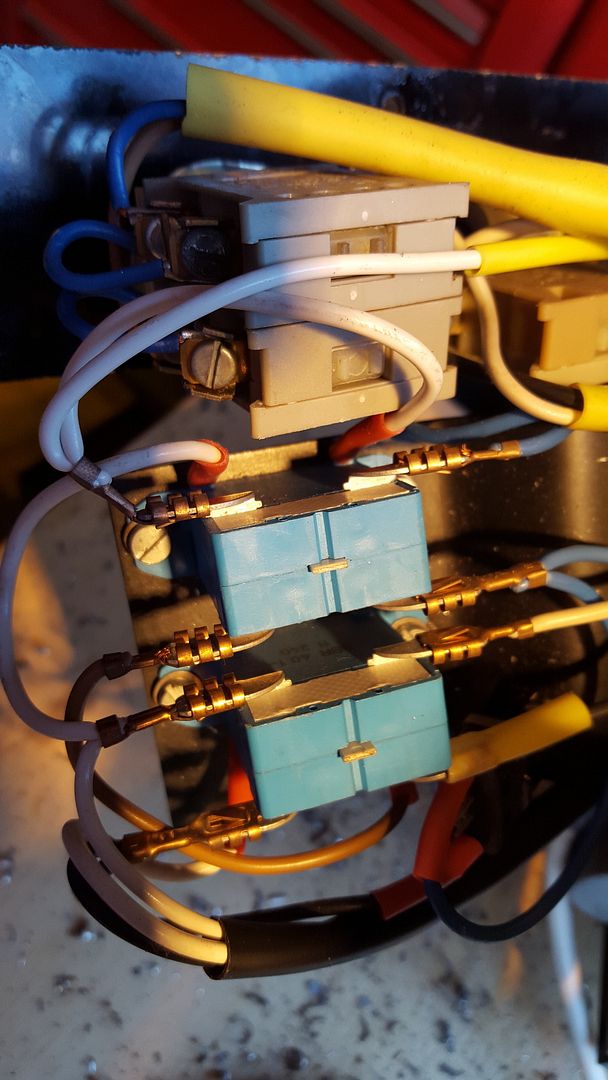

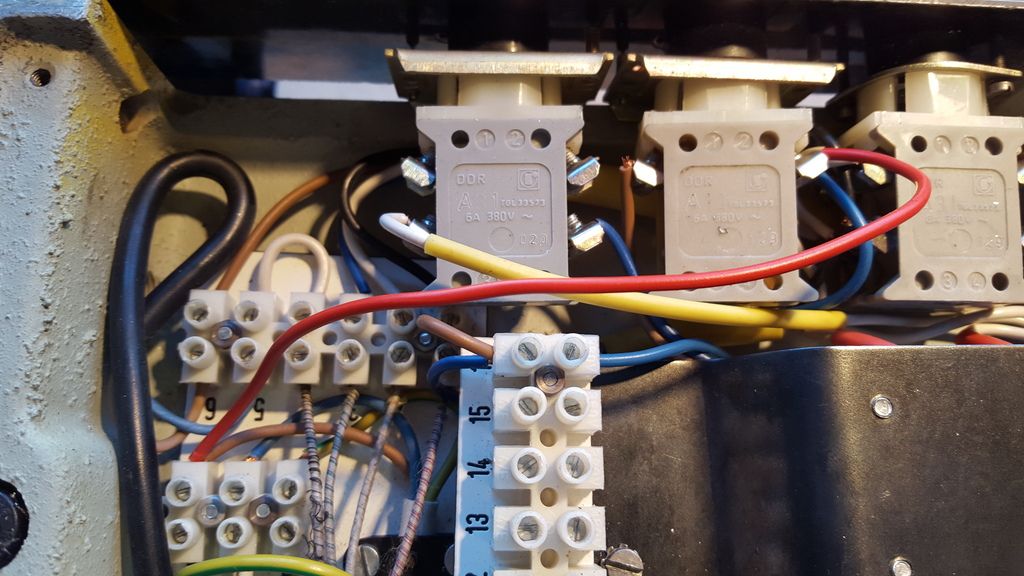

Hi All, Got a slight problem with my Hobbymat MD64 lathe in that is stopped working yesterday. It was like I hit the stop button but it wouldn't switch on again. There was no burning smells and the fuse was still good in the plug. Straight away I conceived myself the motor had gone bang. After an email exchange with Essel Engineering (very helpful) I removed the motor this morning to check the centrifugal switch to discover this is a later model and doesn’t have one fitted. So out came the multi-meter and I worked my way through the wiring and the 2 relays. On the photo below, if I pushed in the white centre contact on the lower of 2 blue relays the motor would run.

I’ve check out both relays and they seemed to be working as they should. Now by luck I was checking the voltage to the on/off switch but my multi-meter was set on ohms/continuity rather than voltage. As I touched one of the terminals on the off switch the lather would fire up and run. I have now put in a bridge wire from the live terminal too the terminal on the red stop switch as can be seen on the photo below. This is the red wire.

In this condition the lathe works as it should using the on, off and direction buttons. For obvious reason I don’t want to leave the lathe in this condition, I would rather fix it correctly. Problem is for the life of me I can’t work out what I have bridged/by past. In this condition both relays click in and work and my meter checks tell me the switches are ok. So now I’m confused so hopefully this is where you step in and say that is so & so Any help is most appreciated Cheers Steve Edited By Steve_M on 31/12/2015 16:09:05 Edited By Steve_M on 31/12/2015 16:10:01 Edited By Steve_M on 31/12/2015 16:10:33 Edited By Steve_M on 31/12/2015 16:11:22 |

| Thread: Collet help required |

| 27/11/2015 21:13:33 |

Thanks all, I'm really glad it wasn't me going mad.. I'm amazed at the wealth of knowledge out there. I have found the first chuck collet details, which does look Chinese. Looks like hole diameter is set so I will just need to find a cutter of that shank size to fit it.

For the ER style I'm not sure which way to go now. May be buy a ER16 collet and see if it fits or cut my losses and go for a new MT1 collet holder. Problem is there isn't much choice out there for the MT1 stuff, unless some else knows different. Cheers Steve Edited By Steve_M on 27/11/2015 21:14:05 Edited By Steve_M on 27/11/2015 21:41:52 |

| 27/11/2015 18:14:15 |

Thanks all for the quick replies. I'm actually quite please you are having trouble working this out as I've measured them over and over and keep coming up with the same. Am I right is say a ER collet recess should clip/sit into the holding nut lip? (hope you under stand that) Also another photo of the holder nut diameter

Cheers Steve . |

| 27/11/2015 16:50:46 |

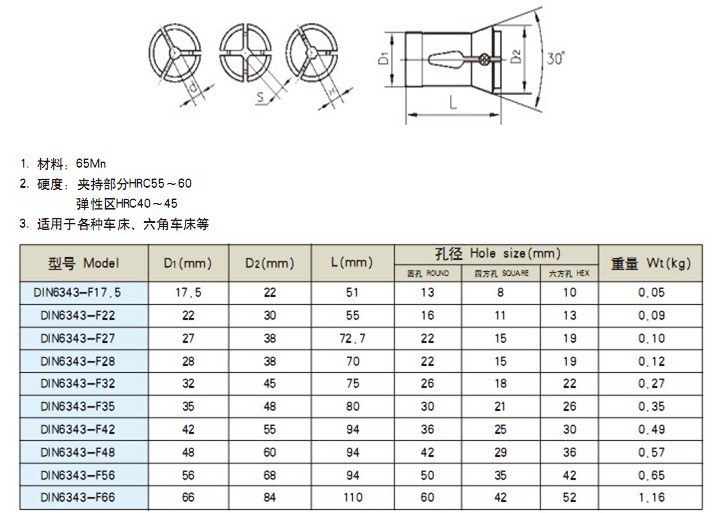

Hi All, As some of you may know I recently required a Hobbymat MF65 lathe and BFE65 mill. Being very new to the engineer I could do with some help trying to identify what collets I require. At the moment I’m well lost and confused. and not having the manual for the BFE isn't helping either. I have 2 collet holders one that bolts on and one with the Mk1 taper. Below is a selection of photos and measurements I have taken. I believe the collets for the mk1 taper are the wrong ones as they don’t seem to sit in the holder very well.

and the 2nd one,

If someone could be kind enough to let me know what these collets are i.e. 5C, ER etc that would be great. Kind regards Steve |

| Thread: Newbie - Hobbymat MD65 Advice Required |

| 13/11/2015 20:28:58 |

Hi all, Just an update on the process so far. After a lot of web browsing, measuring and confirm my MD65 had a 56mm recess I decided to go for the 80mm HBM chuck from RDG tools. This chuck had recess of 56mm so if the PCD didn’t match all I would have to do is drill 3 new holes. This was the closest chuck I could fine. The PCD looked pretty close to what I measured about 0.5mm out from the spec on the chuck but being a newbie I wasn’t 100% sure on my measurements. After some super delivery from RDG the chuck was with me, so time to line it all up. And if by magic the 3 front mounting holes line up prefect with the standard back plate. I’ve replaced the supply 50mm fixing bolts with some 60mm ones and tighten it up in place. I’ve put a dial gauge on there and the chuck is running true. I’ve not turned anything yet but will do over the weekend. So the chuck is a direct replacement for the standard one which is a right result. So thanks to everyone for the advice, it has been most helpful. Cheers Steve

Edited By Steve_M on 13/11/2015 20:32:07 Edited By JasonB on 13/11/2015 20:33:19 |

| 03/11/2015 21:03:10 |

Thanks all, Some great advice and links there, really helpful. I should be ok now but any problems I'm sure I'll be posting again. Cheers Steve |

| 01/11/2015 16:55:47 |

Hi All, I'm new here so a quick introduction and hopefully a few of you can help out with a bit of advice. I've just acquired back my dad's old Hobbymat MD65 lathe and BFE65 Mill attachment. He gave it away some 15 years ago to a friend of his. This Lathe hasn’t been used since then but is still in good condition, all the slides and bed where covered in oil so they haven’t gone rusty. This has now got a new home in my workshop but I have got a few bits missing. The main one being the chuck! So bit of a problem at the moment. The lathe runs fine, not tried the mill yet but will in due course. So I need to fine a chuck for this, at the moment a 3 jaw will be fine as I will only be doing small turning work. Maybe a 4 at a later date. The original clutch back plate is still on the machine, same as the photo below.

So can anyone recommend a chuck that will fit on this or will I need to change the back plate too? I’ve been looking at the following two, **LINK** **LINK** Does anyone know if this will fit ok or have any other recommendations? Any advice is most welcome as I’m a bit out of depth at the moment. Cheers |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

>

>

Register

Register Log-in

Log-in