Member postings for bugbear6502

Here is a list of all the postings bugbear6502 has made in our forums. Click on a thread name to jump to the thread.

| Thread: Material source needed |

| 11/04/2016 18:28:16 |

I was waiting for delivery of a box of mixed roll pins. Waited and waited. Went to eBay to check my order, and chase the seller. Yep - still in my Watch list. They arrived today; for anyone following along, I can confirm that they're certainly harder than my fuel line, but still eminently soft enough to file, so I won't need to follow up my musings on gas-hob annealing.

BugBear |

| 04/04/2016 08:45:28 |

In case anybody else is looking for materials, I can say that the fuel line is probable just mild steel,is super-annealed, with an OD of 6mm and ID around 3.7mm. BugBear |

| 02/04/2016 07:54:21 |

Posted by peak4 on 02/04/2016 00:49:36:

Posted by bugbear6502 on 30/03/2016 13:42:51:

I was considering recycling the telescopic aerial from an old radio (chrome plated brass). BugBear If you have a military surplus dealer round your way, try sections of tank/Landrover radio aerials; they are made of painted, copper plated, spring steel tubing, rather than chromed brass. How interesting - thank you. BugBear |

| 01/04/2016 17:14:02 |

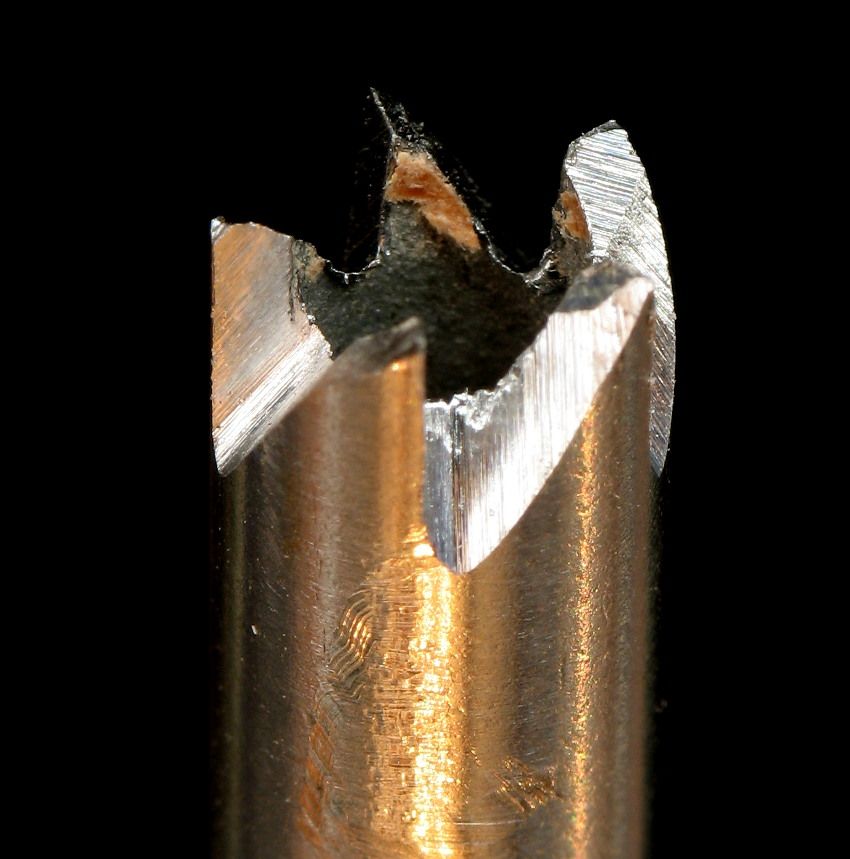

Fuel line turns out to be really well annealed so you can bend it;

I have made a prototype hole saw; a friend gave me some scrap engine fuel line, which turns out The OD is 5.5mm, I don't know the ID. I filed 5 teeth around the circumference, with each tooth face on a radius. On trial, the problem (shared with the commercial versions?) is that you have a saw with no means of removing the sawdust, so you have to keep withdrawing the bit to brush dust off the bit, and to (try to) blow out the hole. So I returned to my teeth filing, and with the tube raised high in the vice, used a 45 degree slope to make a VERY large gullet on each tooth for the dust to go in. The dust still has no means of actual escape, but the teeth hold more now. This seems to work OK.

PS Macro photography makes your filing look awful! Edited By bugbear6502 on 01/04/2016 17:14:34 |

| 01/04/2016 09:24:56 |

Posted by HughE on 31/03/2016 23:27:21:

What about these http://www.highlandwoodworking.com/set3hollowscrewextractors.aspx Just made one for 8 guage screws but i have a lathe which helps

I have a box of cheap (£3.99 for 120) roll pins coming, and a friend just came into work with a couple of feet of scrap stainless steel aircraft fuel line. BugBear |

| 31/03/2016 13:57:26 |

Posted by Hopper on 31/03/2016 13:15:23:

Sounds like maybe a piece of automotive steel fuel line would be about the right diameter for what you want. You can buy it at auto parts stores or wreckers etc. I'd never heard of it! BugBear |

| 31/03/2016 08:50:35 |

Posted by colin hawes on 30/03/2016 16:58:28:

Only a few days ago I made a hole saw from a roll pin to work on brass about 1/4" thick. I cut the teeth with a dremmel grinder by hand using a small grinding disk as accuracy is not important. It did the job much easier than I expected and was just as sharp when I finished. I have neither a Dremel nor a (running) lathe. On another forum it was reported that a brass tube is (just...) hard enough to take teeth that will cut wood. They won't last very long, but brass tube is (of course) extremely easy to get hold of. Alternatively, if roll pins are hardened to an extent that a file won't touch them, can try to anneal them on my gas hob. BugBear |

| 31/03/2016 08:47:45 |

Posted by Frances IoM on 30/03/2016 18:38:05:

using a small soldering iron to heat up the screw normally loosens it enough for easy removal via a lh drill or if any part is proud by gripping with small pliers or side cutter Both the screws I have to remove broke off inside the hole

BugBear |

| 30/03/2016 13:42:51 |

You have both posted an excellent route to making a superb tool "properly".

BugBear |

| 30/03/2016 13:22:49 |

To remove small, broken screws from wood, there's an ingenious gadget called a screw extractor. Here's a pricy commercial version, with very good pictures and a video showing the use. http://www.stewmac.com/Luthier_Tools/Types_of_Tools/Routers_and_Bits/Bits/Guitar_Screw_Rescue_Kit.html https://www.youtube.com/watch?v=bD6ibqWpVCM But I'm dealing with very small woodscrews on a guitar (#3 x 3/8" |

| Thread: Watch making lathe |

| 04/11/2013 13:12:41 |

This recently finished on eBay. To my eye, it's a simple Flexispeed lathe used as a "casting kit" to make a watch maker's lathe. http://www.lathes.co.uk/flexy/ Look at the bearings and collets...

BugBear

Edited By David Clark 1 on 04/11/2013 17:35:01 |

| Thread: New (to me) small, old lathe; how to proceed? |

| 09/04/2013 11:49:40 |

Posted by Michael Gilligan on 08/04/2013 17:57:59:

M14 x 1.5 was also used on the early version of the Cowells Lathe; so it's worth keeping a look-out on ebay, etc. [Cowells owners are tending to update the spindles to M14 x 1.0] Incidentally ... it might be worth getting a Spark-Plug tap, in case you want to thread your own backplates, etc. MichaelG. http://www.tracytools.com/index.php?route=product/product&keyword=spark&product_id=629

Spark plug appears to be M14 x 1.25, not the Simat's M14 x 1.5 BugBear |

| 09/04/2013 10:08:55 |

Posted by Stub Mandrel on 08/04/2013 21:02:38:

Does the 6502 refer to God's Own Microprocessor? Yes - I cut my programming teeth on a Pet 2001. BugBear |

| 09/04/2013 10:07:50 |

Posted by RJW on 09/04/2013 08:33:38:

I use a sewing machine motor and pedal on a watchmaker's lathe, but it's a standby unit I use in France to save lugging a more powerful motor I use here, personally I'd avoid using one on the Simat, it's too heavy! That's a shame - car boots are littered with old electric sewing machine for little money. BugBear |

| 09/04/2013 09:48:24 |

Posted by Lambton on 08/04/2013 17:43:12:

I suggest you invest in a copy of "Using the Small Lathe" by L C Mason. It covers all the basics of buying and using a lathe of the Simat age and type. You will probbly have to machine a chuck back plate to suit the lathe spindle then any suitable diameter chuck can be fitted to this backplate.. If you can only justify buying one chuck always go for a 4 jaw independent chuck..

I already have "The Amateur's workshop" (Ian Bradley) and "The Amateur's Lathe" (Sparey), along with several older books, and a few years worth of 1930's and 1950's MEs. Should I (still) add the book you recommend?

BugBear |

| 09/04/2013 09:44:17 |

Posted by RJW on 09/04/2013 08:33:38:

I have a simat 101 here and have just found the manual for it, once I get scans of it done, I'll happily Email a copy to you, I remember someone asking on here about the manual too but don't know where that thread is now!

That would be VERY much appreciated. The info pack from [email protected] is £35 which is more than I paid for the lathe! BugBear |

| 09/04/2013 09:36:02 |

No pictures, didn't happen:

BugBear Edited By bugbear6502 on 09/04/2013 09:38:47 |

| 08/04/2013 11:56:56 |

I've read about model/small engineering, but never owned a lathe.

At a local sale I picked up a "Simat 101" lathe (30.00 GBP which I think is cheap). |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

BugBear

BugBear

.

.

Register

Register Log-in

Log-in